Nyakabingo Mine’s Tungsten extraction continues to elevate Rwanda’s global standing

In the high mountains of Shyorongi, located in Rulindo District, tungsten ore is extracted from Nyakabingo Mine—a site that has been active for years. As Mr.Justin Uwiringiyimana, the General Manager of Nyakabingo Mine, explains, the history of mining in the area dates back to the colonial period.

He states, “Due to land displacement caused by the steep nature of these mountains, people who lived here,especially during the colonial era—discovered tungsten deposits in surface layers. At that time, mining started as a simple collection of these minerals, which were then sold. The mine began yielding production of approximately 10 to 20 tons.”

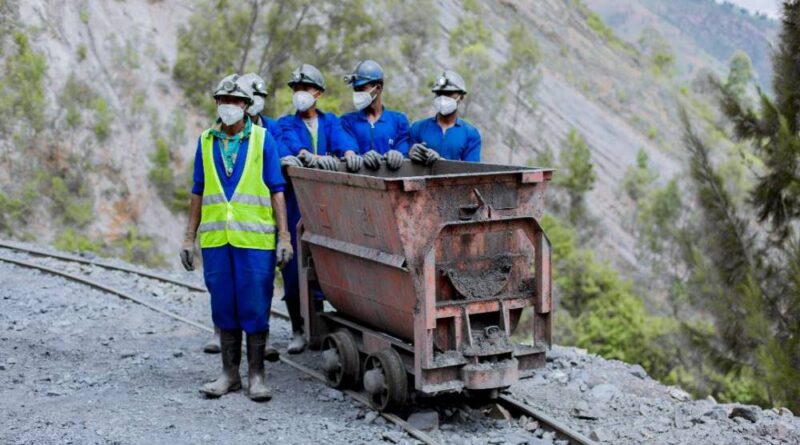

The development of tungsten mining at Nyakabingo Mine has been significantly boosted by technological advancements, with modern equipment replacing traditional tools.

“A large investment has been made in these tools, alongside considerable efforts to ensure workplace safety. We have also prioritized training and upskilling our workforce. Today, all our supervisors have undergone extensive training,” he added.

Nyakabingo Mine employs over 1,800 workers, with some earning over 7 million Rwandan Francs per month, depending on production output. This has enabled employees to achieve financial stability and personal development.

One worker shared his experience, saying, “I have worked here since 2021, and this job has transformed my life. I have built a home, acquired land, and invested in various projects thanks to my earnings.”

The mining process involves the use of Locomotive machines to transport extracted sand from underground tunnels. The sand is first washed, then filtered to separate valuable minerals. The refined tungsten ore undergoes laboratory testing to ensure quality.

Specialized machinery is used to further separate tungsten from waste materials, ensuring a high-quality final product. Once quality tests are completed, the processed minerals are dried using industrial machines and packed into designated bags.

“On average, we extract between 3.5 to 5 tons of tungsten per day, with an estimated daily production of around 4 tons. This means that every six days, we can fill a 24-tons container for export. Even when facing logistical challenges, we consistently achieve this export volume,”Justin explained.

Once processed, the minerals are ready for international markets. Currently, Nyakabingo Mine is the leading tungsten-producing mine in Africa.

In 2024, Rwanda ranked among the top six countries exporting tungsten globally. Of the 1,200+ tons exported last year, over 1,107 tons came from Nyakabingo Mine alone.

Current geological surveys indicate that Nyakabingo Mine holds enough tungsten reserves to sustain production for at least the next 40 years.